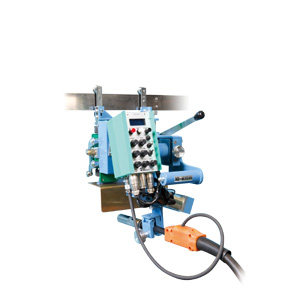

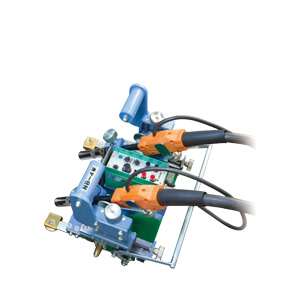

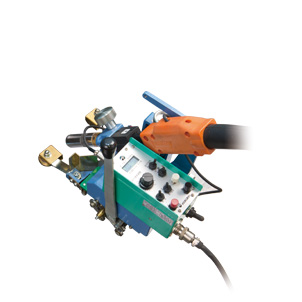

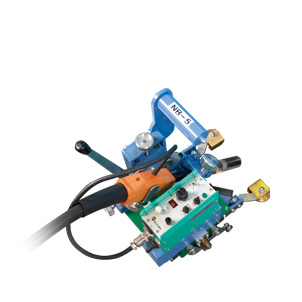

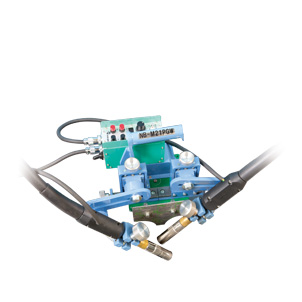

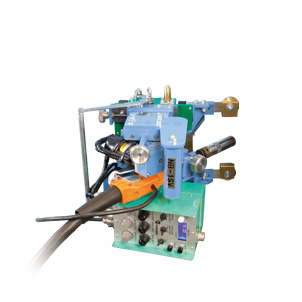

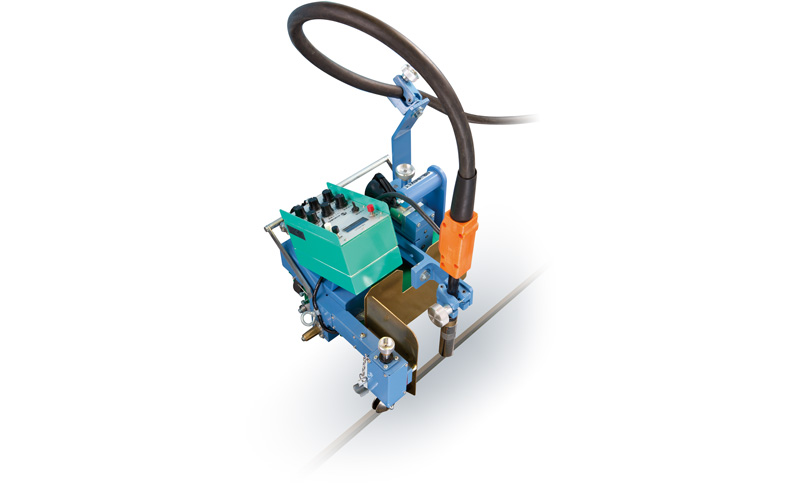

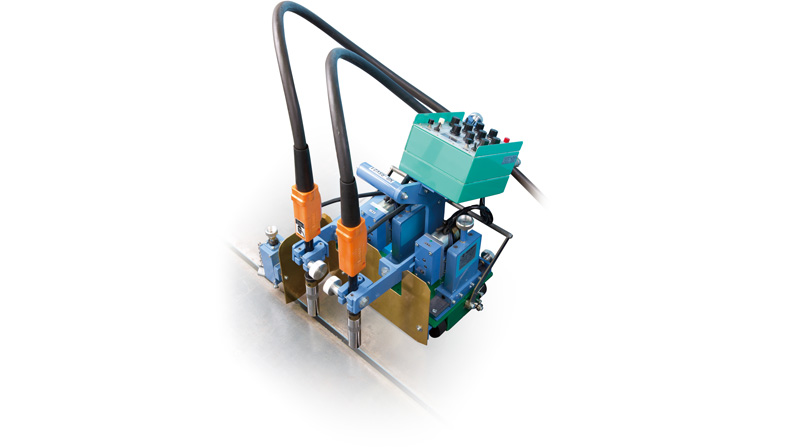

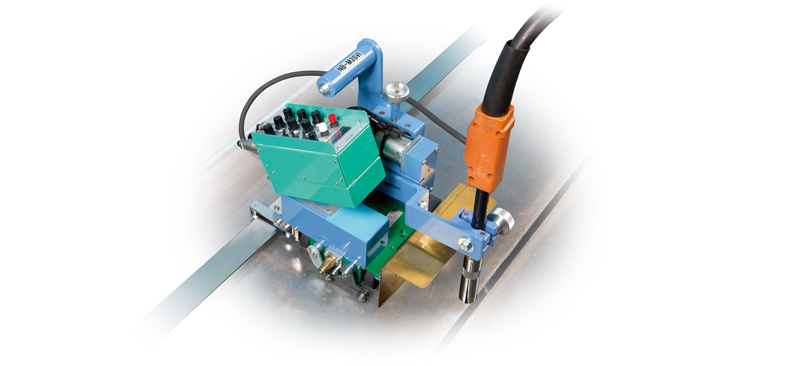

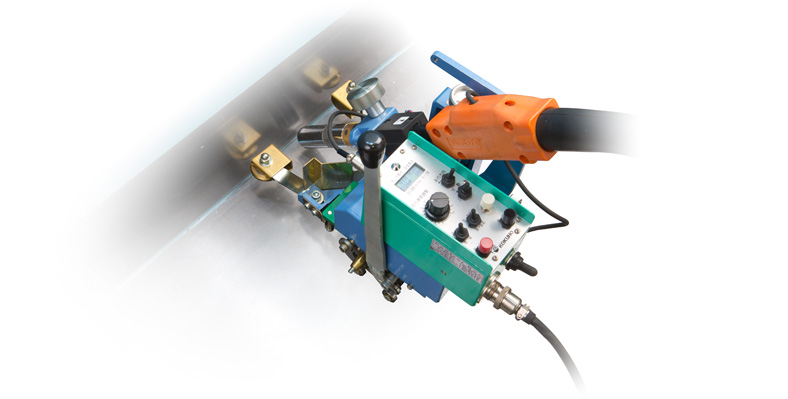

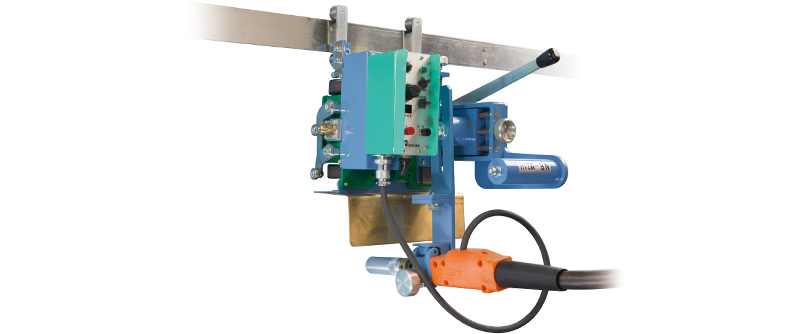

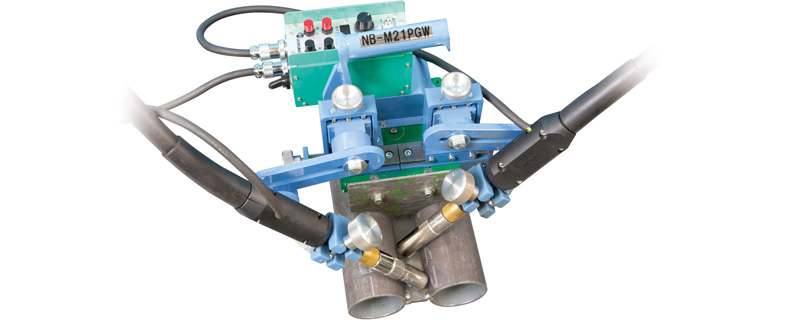

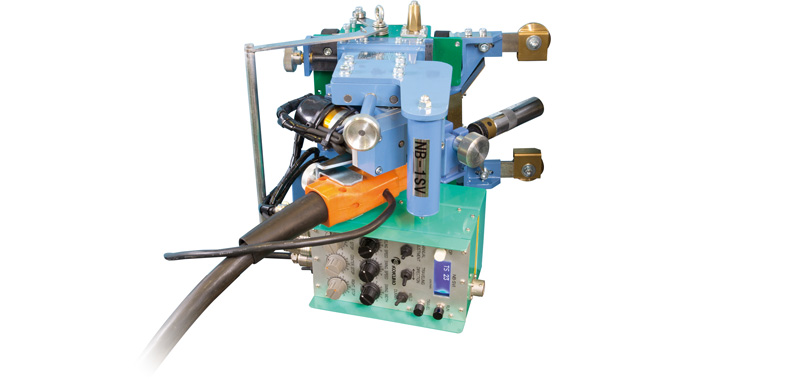

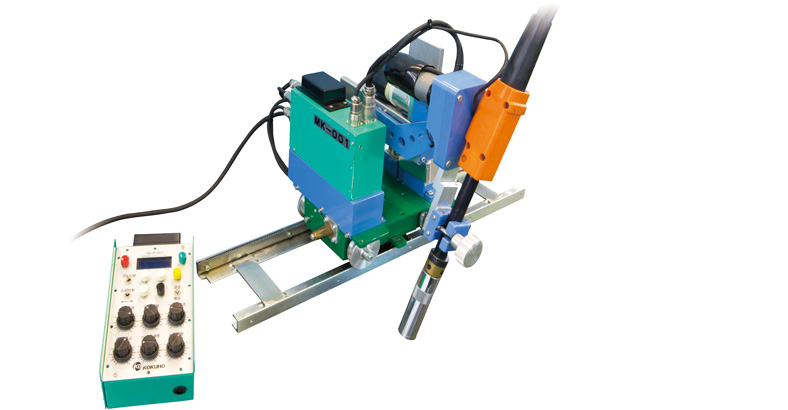

NB-M21N ZERO S

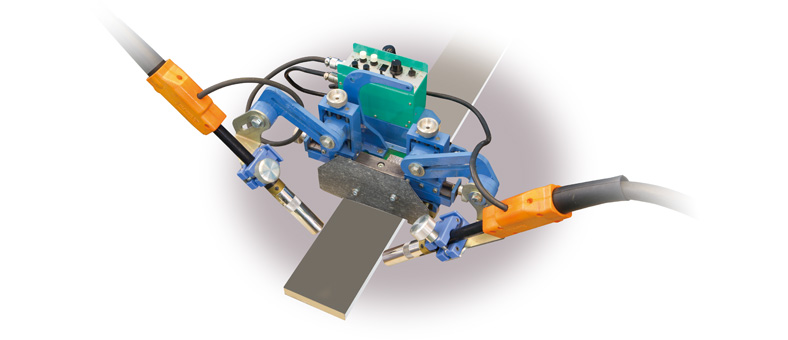

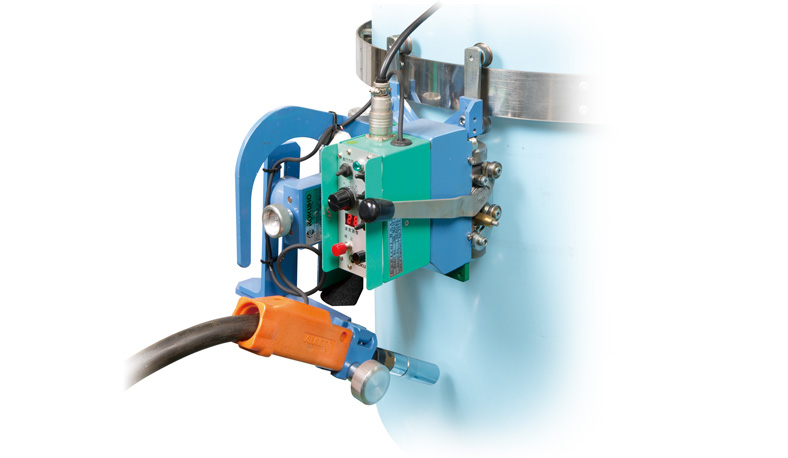

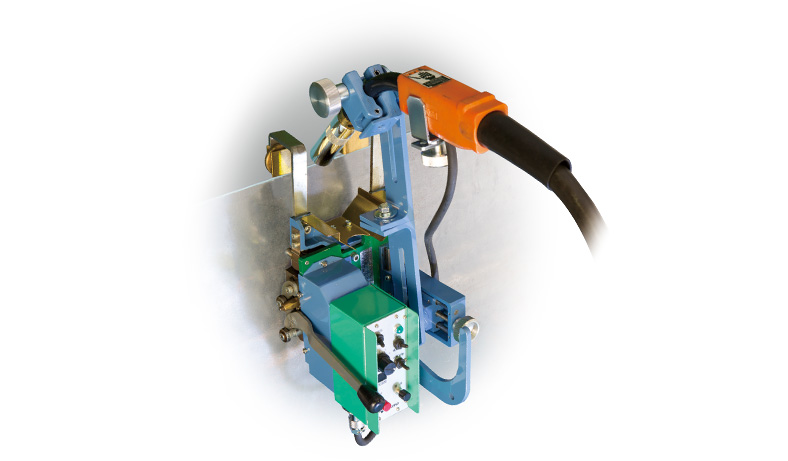

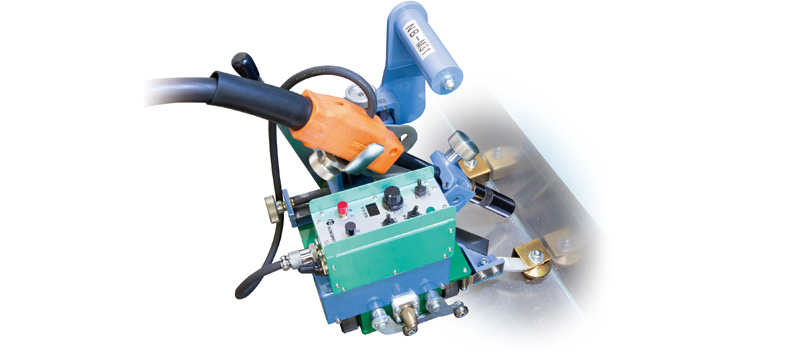

Welding mode: Horizontal and vertical fillet

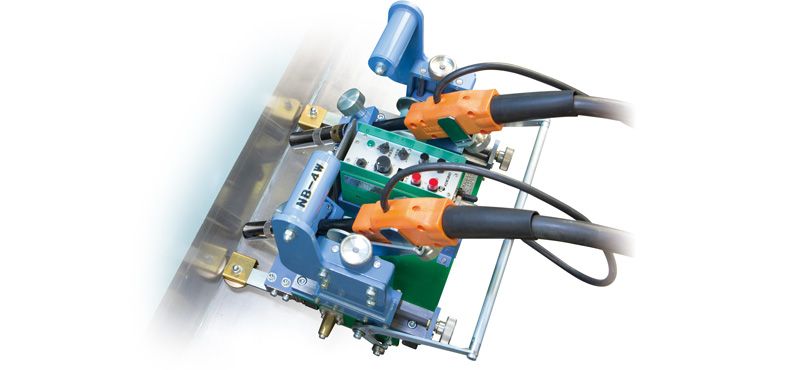

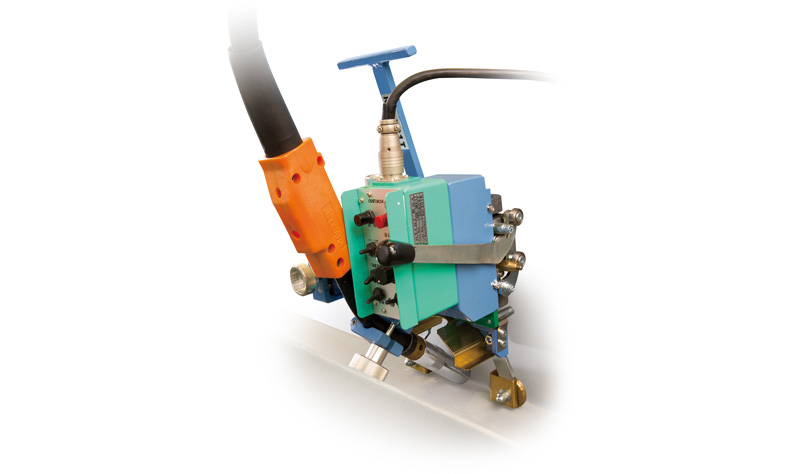

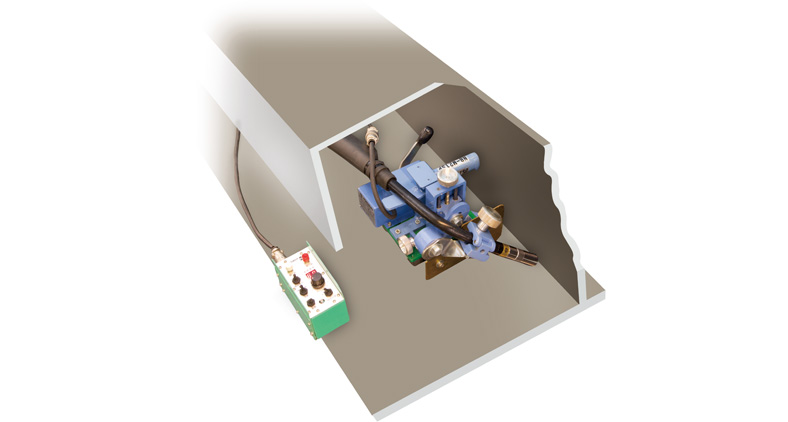

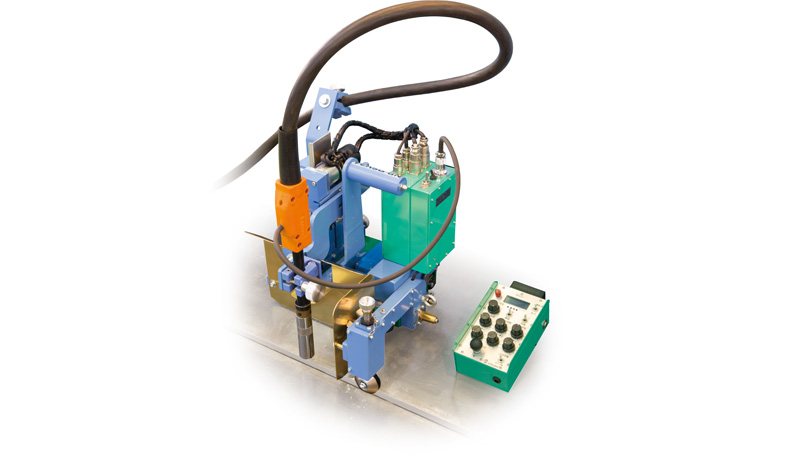

The NB-M21 ZERO S has the weaving mechanism added to the same functions as those of the NB-M31 ZERO S. The weaving mechanism enables horizontal multiple-layer fillet welding and eliminates unwelded portions in vertical fillet welding. Compact, light, and easy to carry with the result of improved working efficiency. Particularly effective for welding longerons in ships and short members in bridges and buildings.

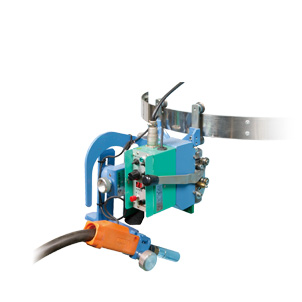

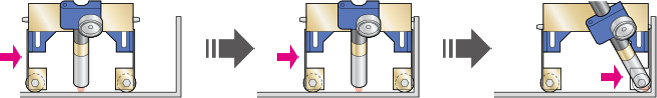

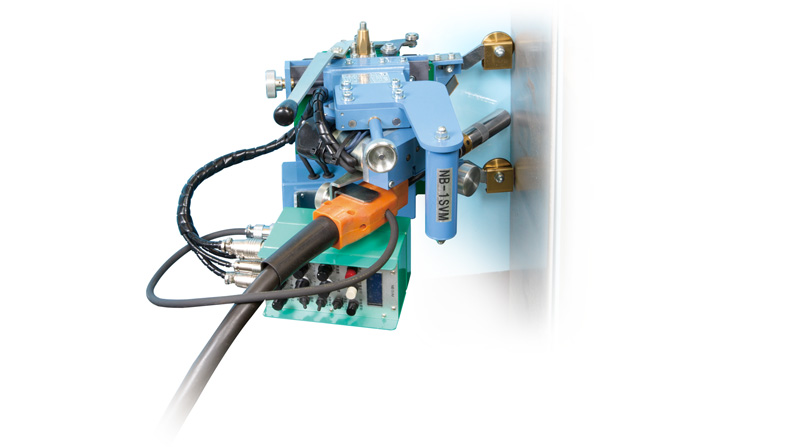

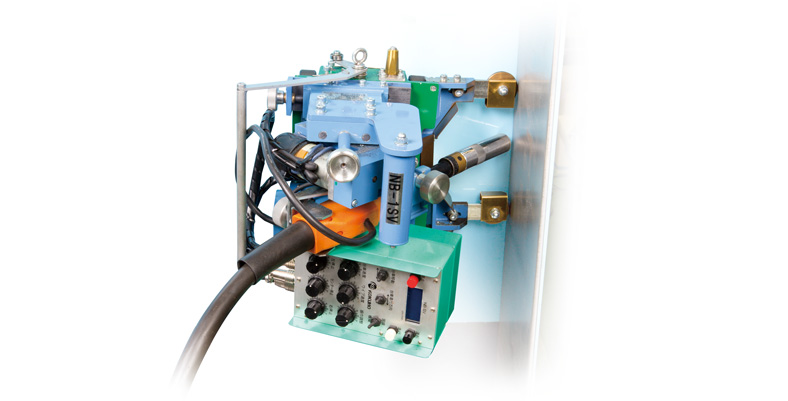

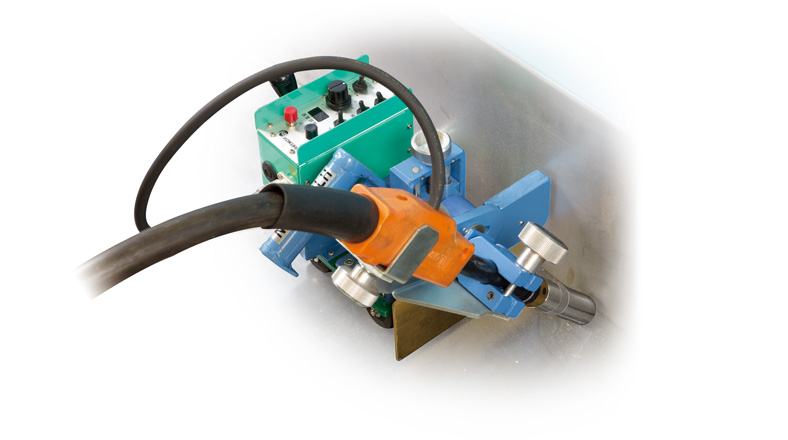

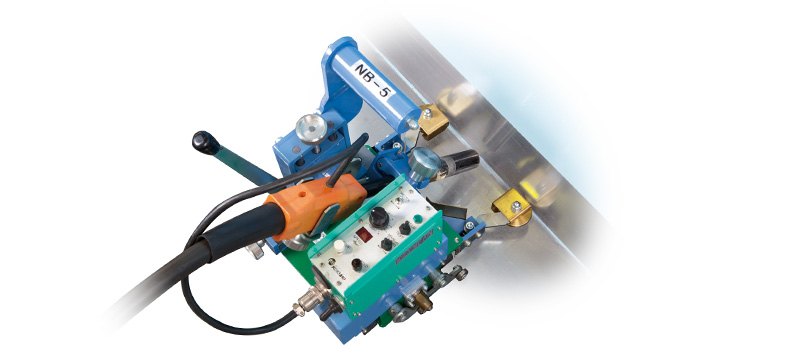

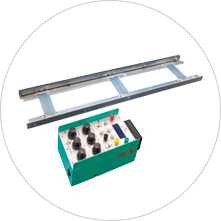

From End to End Fillet Welding

Specifications

| Mass | 6.5kg | |

|---|---|---|

| Dimensions W x L x H (*1) | 245×182×223mm | |

| Bottom gap (to the material) | 5mm | |

| Attractive force | 23kg | |

| Torch adjustment range | Back & forth direction | 10mm |

| Up & down direction | 10mm | |

| Setup angle in X direction | Fixed at 45° | |

| Setup angle in Y direction | Fixed at 45° | |

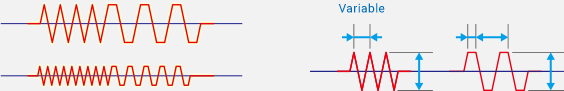

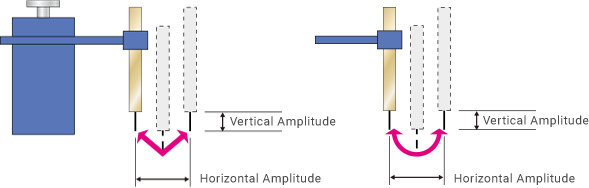

| Weaving | Swing angle | 45° |

| Swing width | 5mm | |

| Swing speed | Semi-fixed installation | |

| Stop time | - | |

| Traveling speed | 9 ~ 55cm / min. | |

| Control power supply (Input) | AC 100 ~ 240V 1A | |

| Torch swing angle | Adjustable to ±16° from center to both ends | |

*These specification are subject to change without notice.